What’s Causing Your Diaphragm Pump Problems?

Diaphragm pumps are used across a variety of product applications, but all pumps are destined to experience operation issues. While these issues range in severity and type based on the product compounds, pump material, location, etc., there are a few common issues that could explain why your pump is no longer working properly.

Loss of Suction (Waste Oil) – Loss of suction in waste oil systems is one of the most common issues experienced by both shops and lube trucks. There are two main causes for this.

1. Y-Strainer Clog – Most commonly used in waste oil systems, the Y-strainer’s purpose is to capture trash (metal shavings, leaves, cigarette butts, etc.) before it enters the diaphragm pump while being transported from equipment to the waste oil tank. However, these strainers often go uncleaned for much longer than is recommended (~weekly), causing a buildup of trash. Ultimately, this will lead to a loss of suction, slowing down your team and causing time mismanagement and frustration.

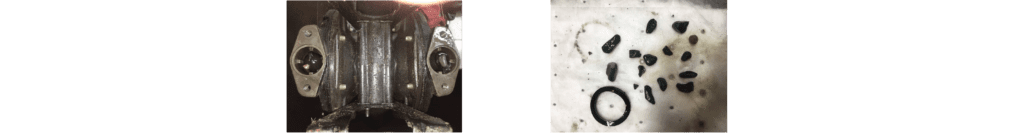

2. Chamber Debris – This issue usually occurs on outdoor job sites where pebbles, large sediment, and/or sand is found. When removing waste oil from a piece of equipment, the technician may lay the hose on the ground in between services, leaving it open to sucking in a variety of objects. This debris then enters through the pump inlet and becomes lodged in between the valve ball and seat, ultimately manifesting as a pump seizure when the size and/or amount of debris cause a lack of pressure.

Pump Seizure – This issue has a variety of causes, but the easiest to identify are thermal expansion and pump corrosion.

1. Thermal Expansion – Thermal expansion can naturally occur for a variety of reasons, the most common being temperature differences in product, as related to their storage and transport line locations. For example, if a shop stores their new oil outside or immediately against an exterior wall during the winter, that product will be a much lower temperature during the morning hours of operation as compared to its temperature during the early afternoon, because the environmental temperature increases. This cycle of cold-hot-cold-hot product moving through the diaphragm pump impacts the pump internals, causing them to expand and contract accordingly. When the product expands continuously, the compromised internals become damaged because of built-up pressure.

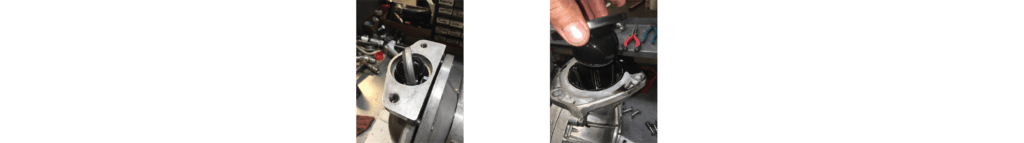

Excessive air pressure is the second main culprit for pump seizure. Technicians can overlook (or possibly even neglect) the pump’s optimal operation PSI from the manufacturer, turning up the PSI in an attempt to complete jobs faster to meet ever-pressing deadlines. While this may work in the short term, the long term effect is damage to the value balls and seats. Under extreme pressure, the valve balls can become lodged in the seat, preventing them from creating pressure. While there are a variety of valve ball materials that withstand a higher pressures/temperature changes, most are susceptible to this issue.

2. Internal Pump Corrosion – When an air compressor has internal condensation, that moisture is transported through the diaphragm pump during operation. This moisture eventually dries out the lubricant that facilitates the pump’s operation, leading to corrosion and malfunction.

So what now?

In the mobile lubrication and equipment servicing industry, helping our customers identify and fix their operational issues is paramount in building and keeping relationships. We actively strive to quickly identify a customer’s issue and provide a long-term solution that is attainable based on their budget and operational needs.

Diagnostic services and repairs can occur on-site at a shop location, or for mobile equipment (lube trucks and skids), the part can be removed and shipped to our location. In both instances, we are happy to offer a “lender” part, which decreases your downtime while we fix your part.

Our solutions range from add-on parts (like thermal expansion relief values and compressor dryers) to custom system upgrades that can help decrease part failure in the long run. We also partner with leaders in these part industries to ensure you’re getting the best product for your money.

While we acknowledge some customers can fix these issues on their own, we also recognize that business owners/operators have packed schedules and often see the value in letting someone else fix their issue when they are confident in the capabilities of their repair company – and peace of mind is what we strive to provide!

Interested in how we can help? Contact us or give us a call today!