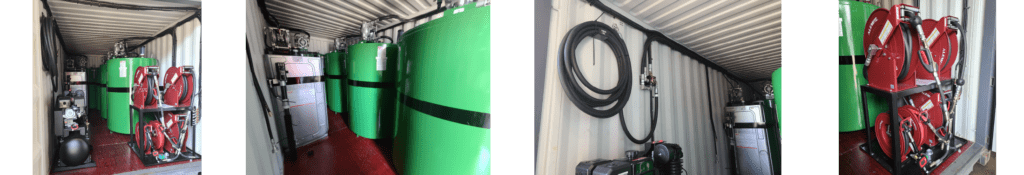

Conex Lube Box: A Unique Bulk Fill Solution

Parallel to lube trucks and skids, businesses sometimes need a long-term (but not permanent) on-site, bulk-fill and bulk storage solution. Something with security, large holding capacity, and the option for unique customizations like work benches and tool cabinets. For over 20 years, Taylor Pump and Lift has been offering solutions like this repurposed Conex box to economic giants across the country.

To learn more about the benefits of these boxes, we asked our Sales Manager, Mitch Queen, and Inside Partnerships Manager, Mickey Wofford, how these solutions came to be and what sets them apart from other mobile lubrication products.

Q: When did we first begin offering products like this?

Mickey: The first unit we built for Castrol was over 20 years ago. It was a large part of the foundation of our partnership with them.

Q: What is our intended purpose when building this product?

Mitch: They need to be large enough to hold the specific types and volumes of fluids the customer needs, while also retaining their mobility/portability. Their primary use is for long-term job site bulk filling of other lube equipment. Some customers have used them as temporary shops or service centers on larger job sites.

Mickey: They also offer storage for parts and filters, and can be customized to include weather-protected, centralized work stations for technicians.

Q: What advantages might this product have vs. a custom enclosed lube skid or lube truck?

Mitch: These are completely different animals. Skids and trucks are for lubrication only (with few exceptions, based on their tank capacities). Conex boxes are geared more towards bulk storage and bulk transfer to those skids and trucks. They’re secure, cost-effective, and can be transferred to the next job site via low-boy.

Mickey: I agree with Mitch. Our trucks and skids are custom-built, so we can always manufacture and fabricate what the customer needs. But the tanks we use in these boxes offer a more cost-effective option vs. tanks that would need to be built from scratch. Additionally, they are double-walled. This product in particular also saves on the cost of a cab and chassis (pending that you don’t need a lube truck in particular).

Q: How does this compare to other solutions that exist in the mobile lubrication market?

Mitch: Honestly, I haven’t seen many options like this offered elsewhere. While repurposing the box itself isn’t unique to Taylor Pump and Lift, our ability to customize the setup and functionality sets us apart.

Mickey: As far as I know, we’re the only ones who make these. I’m sure others could potentially do it too, but ours include not only the layout you need, but also high quality parts from our long-time partners like Alemite, Graco, Raasm, Reelcraft, Turner Tanks, Schulz Air, and Yamada. The product is only as good as it functions, and having these partnerships means we can offer the best possible product to our customers.

Think this might be a good fit for your job or crew? Shoot us a message, and let’s start working together on the solution that’s right for you.