Strategic Equipment Setup: How Your Lube Truck Reel Cabinet Affects Functionality

Much like a house, the layout of your lube truck and reel cabinets can either hinder – or improve – your productivity. During our build process, we identify the quantity and types of lube products you need. Based on that assessment, we construct your lube truck with optimal functionality in mind.

QUESTIONS TO ASK

Often times, our customers are aware of what products they’ll need to service their equipment oil weight, DEF or antifreeze, grease or no grease. But when it comes to determining how those lube products are dispersed and collected, we fully believe that the lube truck manufacturer should be the expert. After all, we build these all day long!

Some questions that go into our thought process when designing the reel cabinet:

- How high can we mount the reels without causing too much strain on the technician?

- Does the operator have to constantly reach around things to access valves or switches?

- How deep should the reel cabinet be to ensure the rest of the lube body layout is also accessible and placed correctly?

- Where should the interior cabinet lighting be placed to ensure appropriate visibility for night time operations?

- Will any of the component placements prevent regular maintenance or quick repairs?

- Will the truck be balanced when full or half-full of product?

- Are there any other requirements specific to this customer’s application that need to be considered, like high-dust environments?

WHAT MAKES TPL LUBE TRUCKS AND REEL CABINETS DIFFERENT?

Because we custom manufacture all of our lube trucks, lube skids, and lube trailers, making unique dimension or placement adjustments is much easier vs. trying to make another, standardized lube truck option work for you. We also have 30+ years of experience that support our setup decisions.

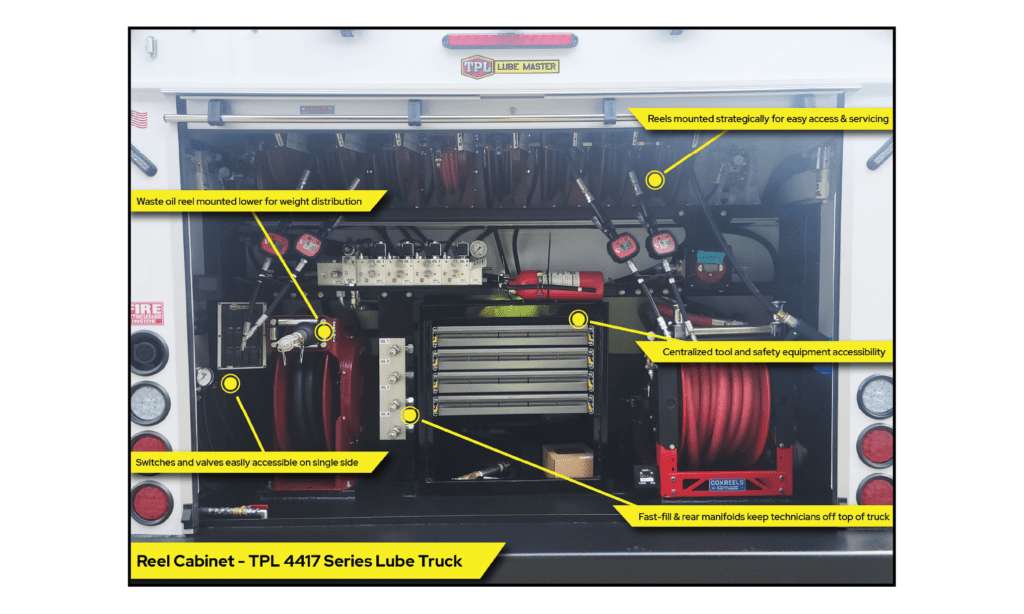

- We mount larger reels, like fuel and waste oil, at the bottom of the reel cabinet to improve overall weight distribution and balance of the truck

- Our fast fill and rear-manifold fill options are designed to keep technicians off the top of the truck, promoting safer work and reducing risk of injury

- All valves and switches are located together (unless otherwise desired by the customer) to make them easily accessible to a single operator

- Toolboxes and safety equipment are centrally located, providing quick and easy access

- Oil product reels are strategically placed to maximize space utilization without obstructing use and servicing

WHY DOES IT MATTER?

It’s no secret that time is money – and the more time your lube truck technician spends reaching for, over, or around things can add up. The same time-saving mechanisms are used by major restaurant and manufacturing companies around the world; checking how many steps are between the coffee machine and the drive-thru window, or how many pillars employees must navigate around before reaching the next destination for a specific product conveyer belt. In our tenured opinion, mobile lube services should be no different.

Functionality considerations are also beneficial when it comes to employee satisfaction and health. Less straining and frustration equates to a lowered risk of workplace injury and higher rates of job satisfaction – a metric that has been proven to directly impact work productivity and performance. By purchasing a piece of mobile lube equipment that has these considerations intrinsically built-in, you already have an advantage that benefits your team and timelime.

READY TO BE A STEP AHEAD?

If you’ve been considering adding a lube truck, skid, or specialty lube vehicle to your fleet, shoot us a message! Our team of experts has over 50 years combined experience, and we are confident in their abilities to build you the perfect mobile lube solution.