Pump-Based Lube Skids: Four Common Misconceptions

Lube skids are used in almost every industry across the country – fueling and greasing everything from airplanes and tractor trailers, to construction and farm equipment. As a staple pieces of service equipment, it’s imperative that business owners and technicians alike are familiar with how the function and form of each lube skid component impacts productivity and, subsequently, profitability. To do this, there are a few common misconceptions about pump-based lube skids that we want to illuminate, and hopefully, create clarity when it comes to determining which lube skid and/or system is right for you.

Misconception #1: Pump-Based Systems Cause Premature Compressor Burnout Due to Constant Use

While it’s true that air-based systems don’t require continual compressor use, they do require a certain pressurization level in order to operate at all. In an air-based system, you use air pressure within the tank to literally push or pull the oil in/out. If the pressure inside the tank falls below a certain level, the entire functionality is halted until the pressure rebuilds.

This means your technicians have to either (A) pressurize the tanks before leaving the shop, potentially causing a safety risk driving around with fully-pressurized tanks, or (B) have to wait once on-site for the tanks to pressurize. This leads to what we call “drip downtime” – small increments of time spent in-between tasks that ultimately adds up to a loss in productivity. Add that to the inevitable time needed to re-pressurize during day-to-day operation, and you’ve probably got a few hours that could’ve been better utilized.

Additionally, technicians and businesses alike are on tight timelines, which can often force technicians to over-pressurize their tanks in an attempt to fill the equipment faster. While this may not seem like a large issue, it can actually add air into the oil, causing it to froth. Much like adding air or other molecular components to a car engine’s oil, this mixture has the potential to cause mechanical damage over time to very expensive pieces of fleet equipment. While recognizing that continual compressor usage does wear the compressor itself, one must also weigh the above risks against it. Are you more willing to replace a compressor, or an excavator?

Misconception #2: Pump-Based Systems Are More Likely To Malfunction Due To Varying Pressures Ratios

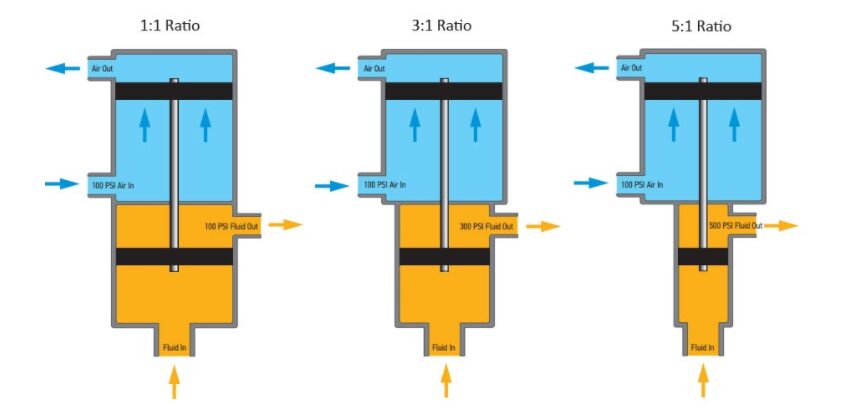

Pump-based lube systems use on-demand air pressure to push or pull fluids at certain ratios. Piston and diaphragm pumps come in a variety of ratios (1:1, 5:1, etc.), which indicate how much air pressure is being pushed in vs. how much pressure is being pushed out.

For example, a 5:1 oil pump operating at 100 psi yields 500 psi of fluid being pumped out.

This ratio exists to increase the amount of GPM (gallons per minute) that the lube technician can fill, saving time on each job. The type and weight of fluid being pumped, along with the hose length (distance needed to travel), outdoor temperature, and available air pressure are all factors that should be considered when choosing a pump. At TPL, our standard lube skids come pre-built with 5:1 oil pumps with a recommended 60 psi for optimum production – resulting in a steady, safe flow rate during fill ups.

While it is possible that varying pressure rates (which are intrinsic to pneumatic pumps) have the possibility to increase air compressor fatigue, when operated at the recommended levels and properly maintained, the risk of total system failure is very unlikely. But in case it does happen, we offer an industry-leading warranty on all of our fluid-dispensing parts, along with in-house repairs and loaner pump availability.

Misconception #3: Pump-Based Lube Skids Weigh More

Pump-based lube skids do not weigh more than air-based ones simply because they have pumps. Air-based systems require internal tank cylinders to facilitate pressurization, which are equitable – if not heavier – than standard oil pumps. This particular misconception concerns operators who want to put their lube skid in a service-body truck without requiring a CDL. Despite being constructed with American-made steel, our standard lube skids come as light as 765 lbs.

Misconception #4: Lube Skid Footprint Isn’t Important As Long As It Gets The Job Done

Lube skids exist for function – that much cannot be denied. Their aesthetic and layout are often secondary or tertiary concerns. But here at TPL, we recognize that part of product development is addressing the space in which the consumer has to operate their equipment. Awkward, bulky dimensions and ill-considered layouts contribute to technician fatigue and improper maintenance due to piece/part inaccessibility.

Wondering if one of our lube skids is right for your business? Contact us for a quote or check out our standard lube skid models for more info on our offerings.