A Look at the New Fluid Manager For Lube Trucks

If you follow us on Facebook, you’ve already heard a bit about the new Fluid Manager tool that we are adding to our fuel lube trucks.

The a big picture description of this new tool is that it will help our clients keep a closer eye on exactly how much fluid is in their tanks, how the dispensers are working, and also allow them to perform regular maintenance tasks in a far more efficient, convenient way than ever before.

In this post, though, we’re giving you a much closer look. Think of it as a tutorial on how to use the Fluid Manager to its best advantage, making your lube truck from Taylor Pump & Lift even more beneficial to your fleet than it is now.

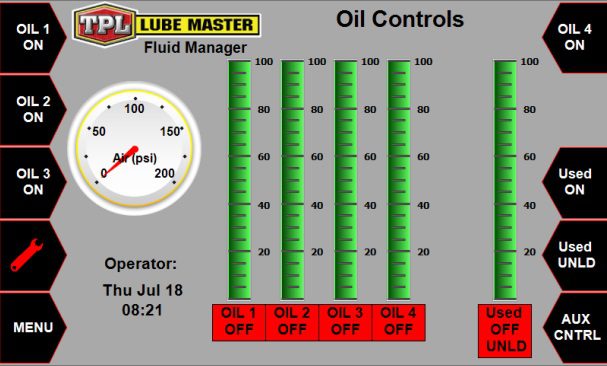

Oil Control Screen

The Oil Control screen is your main source of information about how much fluid is in your tanks and how much pressure the air compressor is generating in real time. Here’s what a screenshot of a topped-off lube truck might look like while not in service:

The functions along the sides of this screen correspond to the device’s buttons, which are heavy-duty and are designed to hold up under the harsh conditions of our clients’ work sites. Your crew can easily start and stop oil flow, switch used oil function, and navigate to other screens.

Other Fluids

The Auxiliary Function control screen is where you will control the flow and monitor the pressure and levels of your lube trucks other products, such as antifreeze, DEF, and fuel. The Fluid Manager tool also controls the truck’s accessories, such as air compressors, site lighting, and other tools.

Diagnostics

The diagnostics capabilities of the Fluid Manager are sure to be very popular with our lube truck customers. This screen (shown below) provides at a glance the total use of each fluid, along with an indicator for air filter quality. No more climbing over your lube truck to inspect air filters to see if they need to be replaced!

If you’d rather review the data later, or if you need to enter the diagnostics information into your long-term records, you can use the convenient USB export function to save the current data onto an external drive.

Each of these screens also features a quick button link to the maintenance screen, where you can view all active maintenance items along with their timestamps. Know exactly what needs attention, what the issue is, and how long it has been since the issue arose.

Other Screens

While these are the primary screens that your fleet manager will access on a day to day basis, there are other important functionalities on the Fluid Manager device as well. A factory setup screen allows the manager to change the number of fluid tanks, capacities, names, and other details, as well as reset the password needed to access the device.

The tank calibration screen allows you to quickly calibrate the tank level sensors, ensuring that you always have accurate information about how much fluid is on your truck for dispensing.

Efficiency, Safety, and Security

The Fluid Manager and the powerful benefits that it gives to a fleet are all about one idea: control. The more control a manager has over the equipment on his fleet’s lube truck, the more efficiently he can use it to maintain vehicles and keep their engines running smoothly.

Starting with the password login feature, the Fluid Manager helps the fleet manager control who has access to lube equipment. Once logged in, the manager can very quickly view the range of critical points that indicate the quality of fluids, their levels, and records of activity.

The tool can also automatically shut dispensing equipment off if fluid levels are too low, helping to prevent damage to pumps.

Customize Your Fuel Lube Truck Today

With the brand new Fluid Manager tool, there are even more great reasons for you to work with us to create your fleet’s next lube truck. Let our experts show you why so many fleets around the country trust us for their lube equipment!